Occupational health and employee safety

In addition to the factory access control security measures, our company also provides employees with legal regulations for workplace passages, floors, ventilation, lighting, work areas, mechanical equipment, fire prevention and disaster prevention...etc. The working environment, accident reporting, investigation and recording are all stated in the company's internal "Occupational Safety and Health Work Code". The company's working environment and employee personal safety protection measures are summarized as follows:

1. Entry and exit control:

1. Our company implements access control management by an entrusted security company to strengthen the control of people, vehicles and items entering and exiting the company. All visitors and goods entering and exiting are required to renew their badges, register and wear identification cards. , employees entering the factory must swipe their cards to ensure factory safety and management.

2. The production site, laboratory, and raw and material sites have separate authority controls, which are managed in accordance with the regulations on personnel entry and exit management in the production area of the factory.

2. Maintenance of various equipment:

1. The company's equipment systems, including air conditioning, high and low voltage electrical equipment, transportation, machinery, fire-fighting equipment, water and gas systems, are jointly developed by the responsible units and implemented according to the plan. The user unit (or responsible unit) of mechanical equipment must carry out regular inspections, maintenance and upkeep in accordance with laws and regulations.

2. Carry out regular inspections every year in accordance with relevant occupational safety and health laws and regulations on hazardous machinery and equipment (such as fixed cranes, forklifts, etc.). Before the expiration of the service certificate, apply to the qualified inspection agency entrusted by the Occupational Safety Administration for regular inspection of the mechanical equipment. If the inspection is successful, the use certificate will be obtained.

3. Disaster prevention measures:

1. Establish disaster prevention, The rescue precautions and occupational disaster notification procedures clearly regulate the responsibilities and tasks of personnel at all levels of the company before and after emergencies.

2. In order to maintain employee safety and health and promote safety and health business, establish an occupational safety and health business manager and an occupational safety and health manager, and report to the competent authority in the jurisdiction.

3. For workers engaged in hazardous chemicals in the factory, implement hazard general education training to enhance the correct safety and health concepts of workers, so that workers can use and store hazardous chemicals. Take appropriate measures in accordance with regulations when handling chemicals.

4. When operating process equipment and using chemicals, provide relevant safety protection equipment, such as goggles, acid and alkali-resistant gloves, safety helmets, and safety shoes to avoid hazards; place them on site Emergency response equipment can be used to deal with abnormalities in a timely manner and reduce the severity and scope of disasters; regular operational inspections should be implemented.

5. When operating in a significantly noisy environment, first evaluate the noise reduction of the project. If it is not feasible or difficult to implement, provide hearing protection (such as earplugs, earmuffs) to employees in the operating area. Wear it.

6. Operators of hazardous machinery and equipment must obtain qualified certificates, conduct monthly inspections and maintenance, and conduct regular inspections every year. Government-appointed agencies shall conduct regular inspections in the factory. .

7. Before the contractor enters the factory for construction, safety and health education and hazard notification will be provided before the project is awarded (if there is a sub-contractor, the general contractor will implement safety and health education and training). The contractor must be informed of the environmental hazards and safety matters that need attention at the construction site. The contractor shall send supervisors to oversee the safety management of the site. The company's industrial safety unit will go to the site from time to time to audit the operation status.

4. Fire safety management:

1. The fire protection system set up in accordance with the law includes alarm system, fire water system, escape system and fire protection manager... etc. The fire protection manager shall coordinate related fire protection matters.

2. In order to implement the maintenance and management of fire safety equipment, in accordance with the provisions of the Fire Protection Law, fire equipment engineers/specialists or professional maintenance agencies are entrusted to inspect the fire safety equipment in the factory from November to December every year. Within fifteen days after the inspection is completed, the inspection results shall be reported to the local fire authority for reference in accordance with regulations.

3. The company conducts fire drills regularly, provides safety and health education and disaster prevention-related training necessary for work, and has emergency escape routes and exit drills in offices and factories. In order to implement daily fire prevention measures, fire management groups are organized into fire fighting squads, safety protection squads, notification squads, evacuation guidance squads, and emergency rescue squads based on the use characteristics of the place, the installation of fire prevention and refuge facilities, gas equipment, and fire safety equipment. , all personnel within the factory must take responsibility for fire prevention.

5. Physical and psychological safety measures:

1. Health examination: New employees are required to undergo a physical examination before joining the job. In-service personnel are required to undergo regular health examinations and special operation health examinations in accordance with the relevant requirements of the Occupational Safety and Health Law and legal regulations.

2. Work environment hygiene Except for the planned smoking area, smoking and betel nut chewing are prohibited in the entire factory, and the factory environment is cleaned and disinfected regularly.

3. Formulate and implement measures to prevent human-caused injuries, protect the health of female workers, prevent diseases caused by abnormal workloads, and prevent illegal infringements at work, to prevent and take care of employees' physical and mental health healthy.

4. Expression of employee opinions: Set up a mailbox for employee opinions, which will be accepted by the management department to allow employees to express their opinions, vent their emotions, etc., and also strengthen the interaction between employees and the company.

5. Sexual Harassment Prevention: In order to prevent and control sexual harassment in the workplace, workplace sexual harassment prevention and complaint measures and disciplinary measures are formulated to maintain and create a safe working environment.

6. Implement automatic inspection:

1. Each unit conducts automatic inspections of machinery and equipment according to the work content. The automatic inspection contents and forms are increased or decreased according to the actual situation, but the inspection contents mandated by law cannot be deleted.

2. Implement inspections before, during and after operations. Inspections before operations are carried out to understand environmental factors, mechanical equipment and operating characteristics; inspections during operations can avoid understanding the existing safety status and whether the failure of existing safety facilities is caused by unpredictable or human factors; inspections after operations, Can carry out work handovers and communicate the current situation of the workplace.

3. Regular (daily/monthly/annual inspection) inspection and maintenance of dangerous machinery and equipment. The government agency shall appoint an agency to inspect the equipment in the factory, and cooperate with the inspectors to carry out the inspection in a timely manner. When equipment is replaced or improved, on-site personnel can only use it after passing inspection and obtaining a qualified use license.

7. Operating environment monitoring:

The purpose is to understand the hazardous factors present in the workplace and their possible impact on the health of workers.

Our company carries out the following steps before implementing operating environment monitoring:

1. Develop an operating environment measurement plan including sampling strategy, starting from basic data collection, raw materials, manufacturing processes, and hazard inventory, and through observation, interview records, and investigation In this way, similar exposure groups are planned, and then sampling is carried out for those who are most likely to be exposed.

2. Confirm monitoring items and locations, including carbon dioxide (CO2), illuminance, noise, organic solvents... etc.

8. Chemical management:

In accordance with the labeling and general knowledge rules of hazardous chemicals, the following chemical management matters are carried out:

1. The safety data sheet (SDS) is placed in a place easily accessible to on-site personnel.

2. Safety data sheets should be updated at least every three years, and update records should be kept.

3. Post visible signs on containers, tanks or storage areas.

4. Prepare a list of hazardous chemicals.

5. Provide education and training on chemical hazard knowledge to relevant workers.

6. Regularly perform priority chemical declarations.

9. Education and training:

1. Employees must participate in safety and health education and training, and the training hours are in accordance with regulations.

2. Personnel engaged in occupational safety and health should obtain relevant certificates and licenses and receive regular refresher training in accordance with occupational safety and health education and training rules.

3. Personnel engaged in hazardous machinery, equipment and special operations shall receive education and training from external qualified training institutions to obtain training hours or certificates depending on the operating conditions.

10. Occupational disaster prevention:

1. Conduct occupational safety and health-related education and training for employees on a quarterly basis to enhance employees’ safety awareness and concepts and reduce the incidence of occupational accidents.

2. Conduct an accident tracking sheet review for occupational accidents in the factory, and ask the supervisor of the unit where the accident occurred to propose improvement countermeasures and prevent recurrence measures for the accident according to the requirements of the accident tracking sheet for review Sign off.

3. Issue inspection deficiencies improvement orders every month for units with safety deficiencies found during inspections, and recruit work safety training courses for deficient personnel the following month to strengthen and enhance personnel safety awareness.

4. Zero tolerance for work-related injuries.Target set to zero occupational accidents in the factory.

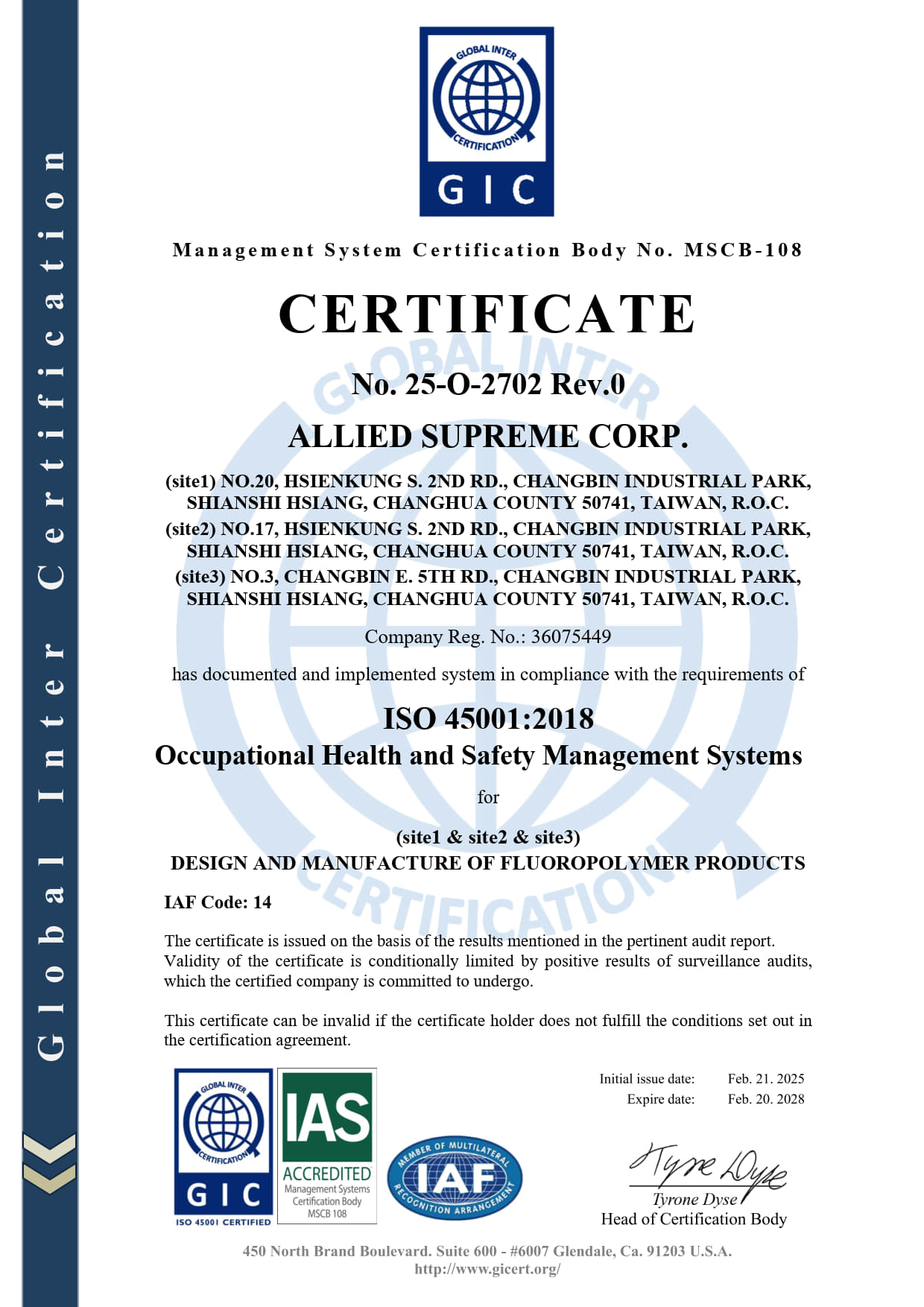

11. We obtained the ISO 45001 occupational safety and health management system certification on December 12, 2024 and passed the certification.